Development and Application of a Computer-Based System for Conceptual Aircraft Design

n5321 | 2025年6月13日 21:53

Cees Bil was born on November 5, 1955, in Oud-Beijerland, The Netherlands. His educational journey began at the Peter Stuyvesant College in Curaçao, Dutch Antilles, and continued at the Zernike College secondary school in Groningen, The Netherlands.

From 1975 to 1981, he pursued higher education at the Faculty of Aerospace Engineering at Delft University of Technology. During this time, in 1979, he became a student-assistant to Professor ir. E. Torenbeek. Under Professor Torenbeek's guidance, he earned his 'ingenieur' degree, specializing in analytical and numerical aircraft design optimization.

In 1981, Cees Bil participated in the Lockheed International Research Institute exchange program, spending six months at the systems engineering department of the Lockheed-Georgia Company. After graduating, he returned to the as a research-assistant. He has held the position of assistant-professor since 1986

1988年的博士论文。

看上去有一点真实感!在洛克希德的系统工程部门呆了6个月。

Computer applications have become commonplace in many areas of design and engineering. Advances in computer technology have led to continuous improvements in computational performance and memory capacity. With the introduction of single-user workstations, either standalone or networked with other processors and peripheral devices, significant dedicated computing resources have become available to engineers at a relatively low cost [Ref. 82].

Beyond the traditional function of solving large-scale numerical problems ('number crunching'), additional computer capabilities have emerged. For example, 4D graphics workstations allow real-time object visualization for animation and simulation. Special-purpose machines for symbolic manipulation have been developed for implementing knowledge-based systems and other applications in artificial intelligence [Ref. 72]. Since the beginning of the computer era, the aerospace industry in particular has played a leading role in applying these new technologies to improve aircraft development and manufacturing.

航空业引领CAE

A Historical Overview

Before 1960, computers were hardly integrated into the design process. They were mainly used for running self-contained analysis programs, usually in a batch-mode environment. Each department or design team had its own specific analysis codes, generally developed and operated by specialists. However, the interchange of design information between these 'isolated islands' was still a manual task, making it time-consuming and error-prone.

In 1950, the technical feasibility of displaying computer-generated pictures on a CRT was demonstrated at MIT [Ref. 99].

By 1962, after significant advances in interactive computer technology, this new technique was implemented in the first experimental drafting system, SKETCHPAD.

里程碑——SKETCHPAD。绘图工具,由伊凡·苏泽兰 Ivan Sutherland 在1963年写作。因为这个成就,伊凡·苏泽兰在1988年获得图灵奖。世界上第一个交互式电脑程序。

In 1965, the Lockheed Aircraft Company developed the Computer-Aided Drafting And Manufacturing system (CADAM) [Refs. 18 and 117], one of the first commercial drafting systems still in use with many aircraft manufacturers today. Around 1980, CADAM capabilities were augmented with a specific 3-dimensional system called CATIA (Computer-graphics Aided Three-dimensional Interactive Application system). CATIA was also developed by an aircraft manufacturer, the Avions Marcel Dassault - Breguet Aviation company [Ref. 22]. At present, a wide range of CAD/CAM systems are commercially available on various types of computer hardware. Drafting and modeling systems are usually associated with Computer-Aided Design (CAD).——绘图建模业务

The introduction of interactive computer graphics capabilities prompted a change in the scope of computer applications. There was a growing awareness of the potential benefits of computer application in the overall design process. This initiated a trend towards integrating self-contained engineering programs—such as mesh-generators for structural analysis, geometric modeling, and NC tooling—into design systems. Typically, engineering programs are interfaced with and configured around central database systems.--好像只是讲讲而已。

Gradually, the role of the computer evolved into a powerful design tool, practically indispensable for the design and manufacturing of today's complex and efficient aerospace vehicles. The infrastructure of computer systems that provides overall support for all design and engineering activities, up to manufacturing, is generally referred to as Computer-Aided Engineering (CAE).

application independent.

Because of their fundamental solution to the problem, computer-assisted engineering systems, such as those for structural and flow analysis (CFD), are also generally applicable. Inherent to using these systems is the requirement for the object to be known in considerable detail, which involves a large amount of data and relatively long computing times. Consequently, these systems can only be efficiently used in the detailed design phase

Computer-Aided Engineering (CAE) has not fully established itself as an accepted design technique in the initial, i.e., conceptual and preliminary, phases of the design process. Several general factors have hindered CAE's penetration into the configuration development phase:

影响CAE应用的三个因数——说得不错!

Heuristic and Intuitive Nature of Conceptual Design: Conceptual design is typically not a predetermined and strictly rational process. Its heuristic and intuitive nature is less suited for the formalized structure required by computer programs.

工程师设计的时候常常是思维发散,启发式、直觉式的,要高度固化,要求输入格式化的数据有难度!——本质上是很多工程师对自己的产品理解得不够,大部分的设计都是维护性质的。只是改原有产品的若干参数而已!

Lack of Transparency in Computer Programs: Computer programs can appear less transparent to the designer. Hidden or obscured design decisions may confuse the decision-making process, leading to results that are not accepted or only accepted cautiously. This is especially true when many design parameters are varied, such as in automated design, where the analysis can become too complex to understand the physical relationships between different disciplines.

工程师对计算机程序搞不清,对这个黑盒子里面吐出来的结果跟填进去的数据之间有什么关系不是很清楚。一些隐藏的、矛盾的参数会把人搞晕,最后获得的结果数据,哪些能用,哪些不能用,不确定。

Need for User-Friendly Interaction: Close interaction between the computer and the designer is essential and requires special attention to a user-friendly communication interface and ease of operation.

交互模式不好!做不到易用性!

我们可以解决这三个问题!

Computer applications in the pre-design phase are generally restricted to (large) custom-coded programs developed and used on an ad hoc basis.计算机应用都是定制的 Since 1965, research has focused on integrating design methods into synthesis programs. A classic example is SYNAC (Synthesis of Aircraft) for military aircraft configuration development at General Dynamics [Ref. 91]. A more recent example is the ACSYNT-program (Aircraft Synthesis) developed by NASA [Ref. 15]. This program also forms part of Northrop's Conceptual Design System (CDS) [Refs. 105 and 106].

Some of these synthesis programs even offer the option to automatically perform sensitivity studies and aircraft sizing. However, the incorporated design methods and their respective input and output variables are pre-selected and cannot be easily modified by the designer. 设计参数不能改,最后application 难以scale up!Therefore, these programs often require reprogramming or additional code for each new application not accommodated by the original program, which resists innovative design. Additionally, the time required to adapt the program may render it obsolete before it becomes productive. Due to the built-in design procedures and processes, designers tend to adjust their way of thinking to the capabilities and mode of program operation.

Essential for the development of a generic preliminary design system that the analysis methods are considered as input to the system, similar to data, rather than being integrated, i.e., fixed, into the system itself. Thus, these modules, embodying the design knowledge, should reside outside the system, where they can be easily modified and reorganized by the designer and tailored to the specific design problem structure and aircraft category. Boeing's Computer-aided Preliminary Design System (CPDS) [Ref. 132] is a typical example of this concept.

Potential Benefits of Computer-Aided Engineering

Although the objectives for introducing CAE may differ per industry and application type, some general areas of practical and economic potential can be identified concerning aircraft design [Ref. 70]:

Reduced Design Time: CAE can reduce the development time needed to introduce a new design. Early introduction and availability, ahead of competitive designs, can be an advantage.

Improved Product Through Better Design: Within a given timeframe, more alternative design solutions can be considered, potentially leading to improved design quality.

Greater Design Capacity: For a given design staff, several design projects can be accommodated simultaneously. A faster response to customer queries and requests is also possible.

Solving Outsized Design Problems: CAE introduces opportunities and capabilities that are practically impossible to achieve in a traditional design environment. Sophisticated analysis codes require computer-assisted pre- and post-processing.

Reduced Design Cost: A reduction in design and development cost can be expected, particularly in the areas of drafting and manufacturing [Ref. 54].

In principle, these advantages also apply to conceptual design. However, even though at least 80% of a project's development and production cost is related to decisions made in the early stages of design, the actual investments during conceptual design are relatively small. Therefore, emphasis is generally placed on improving design quality rather than cost reduction:

Improved Efficiency of the Design Process: Automation of routine and repetitive activities relieves the designer of standard tasks. Formalization of design data improves data exchange between disciplinary teams and downstream design levels.

Improved Design Quality: Within a given time/cost frame, more design alternatives can be evaluated. Sensitivity studies, trade-off studies, and multivariate optimization can be more easily applied in an integrated design environment.

Although the procurement of CAD/CAE hardware and software is costly and its implementation will undoubtedly impact a company's organization, infrastructure, and working procedures, these initial problems do not outweigh the long-term benefits. The implementation of CAE in the aerospace industries and research laboratories is well underway, as a better concept is essential for a better aircraft design.

The Aircraft Design Process

Developing a new aircraft type demands a substantial financial investment. Because of this, the decision to launch a new aircraft project is always preceded by extensive market surveys. These surveys aim to gauge commercial prospects and identify the specific requirements of potential customers for future air transport.

However, conceptual and preliminary design studies are also conducted for other reasons, such as assessing the impact of emerging technologies or exploring the feasibility of alternative concepts, even without the immediate intention of building the aircraft. After all, a genuinely new aircraft type emerges only about every 20 years!

The Design Synthesis 跟电机设计差不多!

Aircraft design isn't generally a continuous or straightforward process; it involves many repetitive procedures and feedback loops.(是不是类似电机的一次、二次、十次、十一次送样?) However, it's common practice to divide the overall aircraft design process into three logical phases, as illustrated in Figure 2.1 [Ref. 124].

The primary objective during the conceptual design phase is to develop a global definition for several design configurations that best meet the overall design requirements.

- A key characteristic of conceptual design is design synthesis: the designer attempts to combine all technical disciplines – such as weight and balance, aerodynamics, stability and control, performance, costs, and noise – into a well-balanced design solution. Since only limited design information is available at this early stage, relatively simple analysis methods, known as Class I methods

- finite-element modeling and computational fluid dynamics (CFD). At this stage, the design staff is typically divided into disciplinary teams, each with their specific specialization. A final selection is made, and the design configuration is "frozen." ——engineering analysis 来了!

- In the detail design phase, the aircraft is designed at a component level, resulting in a large number of engineering drawings. Wind tunnel experiments and structural tests are also carried out. At this critical juncture, management must decide whether to "go-ahead" and build the aircraft, as development costs will increase progressively beyond this point. ——出工程图!

While the general concept of the ADAS system does not restrict its application to a particular design stage, it is primarily intended for conceptual design.

The Search for the Optimum Design

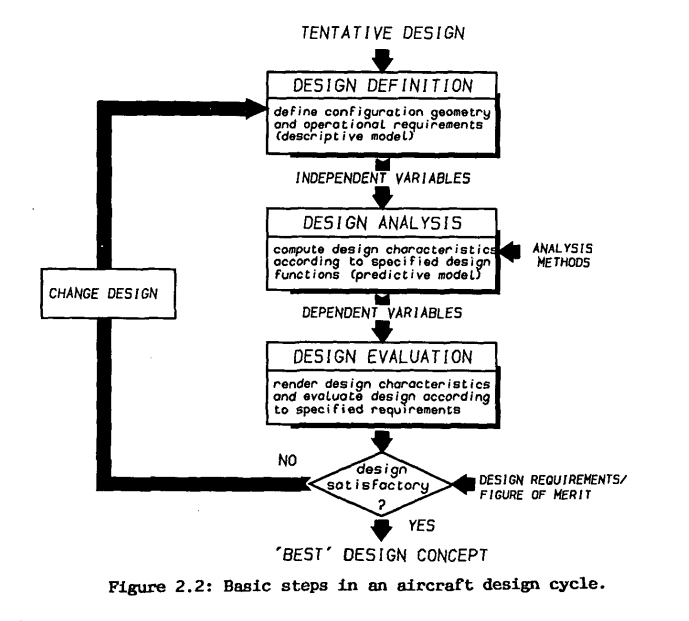

To develop a suitable design system, it's essential to identify the basic activities and procedures involved in the initial stages of design. Design is generally an iterative process that begins with an initial, tentative design configuration, referred to as the baseline design. Given the design requirements and objectives, the configuration is repeatedly modified in subsequent design cycles until a satisfactory design solution is found.

A design cycle, in turn, can be divided into three basic steps:

Design Definition: A new or modified design configuration is geometrically defined in sufficient detail.

Design Analysis: Suitable analysis methods are utilized to compute selected design characteristics.

Design Evaluation: The design is evaluated by comparing the analysis results with the given design requirements and objectives. If deemed necessary, the design configuration is changed, and the process repeats.

search process: design data and analysis methods are manipulated until the process converges on an acceptable design solution. In mathematical terms, four key ingredients are involved:

Independent Variables (Design Parameters): These can take arbitrary values within specific limits. Design parameters can be assigned a value either directly by the designer or indirectly by an executive program. Design data that remains constant throughout a study are called design constants. Typical examples of design parameters include wing aspect ratio, wing loading, thrust/weight ratio, and tailplane dimensions.

Dependent Variables: The values of these variables depend on the independent variables. They represent design characteristics like performance criteria, cost, noise, etc.

Analysis Methods: These define the physical relationships between the independent and dependent variables. Analysis methods can range from relatively simple to extremely complex, depending on the required accuracy and the available input information.

Design Requirements and Figure of Merit: These are used to assess the feasibility and efficiency of the design configuration. Design requirements impose technical constraints that may stem from operational performance, mission requirements, airworthiness regulations, technological aspects, and practical considerations.

It is common practice in conceptual design to select the primary wing and tailplane parameters such that the aircraft meets the defined mission requirements (known as "sizing"). However, it's often found that several different design concepts can represent a feasible design. The entire collection of feasible designs is referred to as the design space. An additional requirement, a figure of merit, may then be considered to select the best possible (feasible) design. This process is called design optimization.

Procedures for Design Optimization

There are three fundamentally different procedures that a designer can employ to search for the best conceivable ("optimum") design [Refs. 113 and 126]:

Traditional Intuitive (Optimum) Design Approach: In this approach, the designer relies mainly on intuition and experience to select and change design parameters.

Advantages (+):

The designer can fully utilize experience, augmented by proven and simple design methods.

Simple or no programming is required.

The number of designs to be analyzed is limited.

Maximum use is made of calculated results.

No a priori choice of one merit function is needed.

Arbitrary, though limited, number of variations and design modifications are possible.

Disadvantages (-):

No guarantee that a real optimum is obtained.

No useful results are produced outside the designer's experience.

It is time-consuming, leading the designer to resist desirable changes in design specifications or previous decisions.

Explicit or Parametric Optimization: This procedure involves generating and analyzing a multitude of designs, each with different parameter values. All designs are subsequently evaluated, and the "best" design is selected.

Advantages (+):

It is rooted in the industrial approach.

Requires relatively simple programming.

The designer has complete control over decisions.

No a priori choice of a single merit function is needed.

Sensitivity of off-optimum design conditions remains visible.

Disadvantages (-):

No guarantee that a global optimum is obtained; it may lie outside the selected design space.

Only practical for a limited number of independent variables (e.g., 3 or 4).

Many designs are evaluated, but only a few are actually used.

The designer is not encouraged to extend the number of variables, as the amount of data to be analyzed increases exponentially.

Changes in design specifications make previously generated results obsolete and are resisted.

Implicit or Multivariate Optimization: This technique requires the design process to be fully automated. The figure of merit and design requirements are quantitatively formulated as an objective function and constraints, respectively. An optimization algorithm (optimizer) changes the specified design parameters (free variables) based on mathematical information acquired during the optimization process.

Advantages (+):

Potentially leads to improved design quality due to the rigorous approach.

Especially useful for multi-variable systems.

Effect of "biased" decisions is eliminated.

Changes in design specifications are easily met.

Disadvantages (-):

Programming and debugging are difficult.

Optimization algorithms are not always effective.

Convergence problems may occur (no solution is found).

No insight into design sensitivity; only one design is obtained.

Inexperienced designers may produce and accept unrealistic results.

In the order presented, these optimization techniques involve a higher degree of design automation, where control of the search process is delegated to the computer. By comparing their pros and cons, it can be concluded that these three optimization techniques are complementary