Really, really, really nice to be here. I think this is the first one of these events I've done in person in a really long time. And it's just wonderful and hello to our hybrid audience out there as well. We know there's a whole bunch of you. But I'm especially glad that we're here today for such an important event, an event that honors Dr. John A. Swanson as a 2021 Cornell Engineering Distinguished Alumni Award recipient.

Dr. Swanson is a triple read classes of '60 to '61, BMI '62, and MS '63. And he joins a small and truly extraordinary group of Cornell engineers. Can we honor with this award for having left an indelible mark on their professions, on Cornell and on the world.

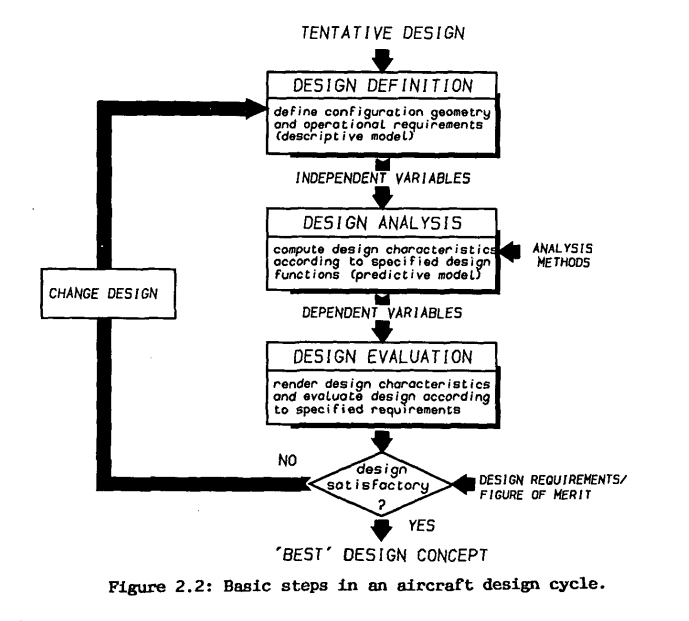

His curiosity and his determination very early in his career led to one of the most significant developments in simulation engineering, as well as the founding of Swanson analysis systems, known today as ANSYS Incorporated, an industry leader in CAD CAM and multi-physics engineering simulation software for product design, testing and operation. And the finite element analysis software that John developed in the late 1960s transformed the way that engineers and designers perform complex calculations and analysis across a broad spectrum of industries.

John has been recognized for his contributions with a number of honors and awards, including the John Fritz Medal from the American Association of Engineering Societies, something that's often described as the Nobel Prize for engineering. That puts him in the same category with a few other people that you might have heard of, like Thomas Edison, Alexander Graham Bell, George Westinghouse, Orville Wright, and no fewer than seven other Cornellians.

And in 2009, John was elected to the National Academy of Engineering, recognizing his accomplishments at the highest level in the field of engineering.

In 1994, John sold ANSYS and he retired as chief technologist five years later? Yes, you're nodding like he retired because the air quotes around "retire" are deliberate since what he's done since 1999 would fill a resume on its own. So it's kind of hard to look at that list of achievements and say, "Oh yeah, he retired, definitely retired."

Speaking personally as well as for Cornell, I am really, really glad that John decided to retire in name only because in the last two plus decades, he's made a second career of engineering education and philanthropy. And Cornell has been fortunate to be a beneficiary of both.

A great advocate for the training of practical engineers, John has spent much of his time working with and investing in engineering programs here at Cornell, at the University of Pittsburgh, where it happens, I taught early in my career and where the John A. Swanson School of Engineering is named for him, at institutions around the country where he shares his experiences and his passion for engineering.

In recent years, he has been a strong advocate for an investor in renewable energy. In fact, earlier today he served as distinguished lecturer for the engineer, sort of the energy engineering seminar, sharing his thoughts on how to move the current electrical utility distribution network, what we usually referred to as the grid, a much greener approach with the use of carbon free resources.

He's donated solar panels to the university. And he inspired and funded a project to convert one of our diesel tractors to biodiesel. Biodiesel. Both of which provided opportunities for engineering students to gain hands-on practical experience. While at the same time moving us closer to a carbon neutral campus and a sustainable future.

John's extraordinary generosity with his time, knowledge, skills, and resources have had an enduring impact here at Cornell and beyond. He supported faculty like Mario Land Van der Meulen in the Swanson Professor of Biomedical Engineering, capital projects like Swanson Atrium and Nuffield Hall and the Swanson biomedical engineering suite and Weill Hall, programs like the Swanson engineering simulation program. And always, always our students, there was support of the engineering student project teams, The academic excellence workshops, and the John A. Swanson undergraduate scholarship.

John has strengthened the educations of so many Cornell engineers and its impact on our students and alumni will continue for many years to come.

And while we're here to recognize today John's contributions to engineering, I hope the engineers will understand if I take just one detour because I can't stand up here in front of you and not acknowledge the Swanson and particularly Janet's incredible support for our College of Veterinary Medicine, for which we are all so, so very grateful.

John, on behalf of Cornell University, I congratulate you on this most deserved honor. Thank you from all of us for everything you've done for Cornell, Cornellians, for the Cornell mission and for our world.

Okay. Thank you.

Alright. So first of all, let me just say on behalf of the college, welcome. This is a relatively new award for us and this is the fun part for me actually, is having a role in this conversation with John. I guess I can take this off. We're just going to say no. Was going to say, you can have it having this conversation. The John is actually going to be a highlight of my day and maybe my first year as dean of the college.

So what I'd like to do in the next few minutes you've got together John is to just sort of first take you back to where you came from, sort of the underpinnings of your values, your success, your impact on. I want to get a sense for the middle, the things you did at Ansys and so forth. But ultimately want, you know, maybe force you to help me look to the future as we think about clean energy, think about sustainability. In fact, think as a campus about how we made the campus carbon-neutral in a living laboratory contents. So that's sort of the arc of what I'd like to do. So let's start to the start, right?

So I've read in several places the important role your mom played in your upbringing, your commitment to excellence. I wonder if you could tell us a little bit about that, but that's sure they have. There is a teaching award here at Cornell, the Darcy Jewish Watson Award, and the fine print. And Nat says, the way I look at is an expectation of excellence. We weren't said we have to. This is just part of the environment. You will be number one. You will do well. You will say, Oh, yeah, the things that are my basic core came from just that expectation. There was not really discussed. It was just there, there were no question about it. My father died when I was four, so she was a school teacher. She became an elementary principal, lasted about six months of Dan decided she'd rather teach students. And I understand completely why that is. And I'm sure you do as well. But anyway, she was the focus and she did a good job. Hence, the recognizer and UI, I have enough of a core which is extremely strong, but it's not forced because that's, that's who I am. That there was no other choice. So I am who I am as somebody once said, move forward.

Thank you. Well, that's pretty good. So then so you came to Cornell. That will tell how little the mode that dwell and let, let, let me explain the selection process. Bearing mind a school teacher of fifth grade in a small file. I think there's a mike. I think something has gone back and you're going anyway, a small school, 12 in our graduating class, 3 in my older brother's graduating class. So not a high revenue position. But then also questions. You came to Cornell. Cornell was, was a desire, but not necessarily achieve. Actually we rank to colleges by how cheap they were. And so I had three colleges in New York state. One up in the North, one in Albany and one here I won't name names. But then the good news was I got National Merit Scholarship, was of course, the game changer, somebody at that time. So let's invest in the future. And this is what they caught. I hope that, I hope they're happy with it. Yeah. Sorry.

So Cornell was it. Now, I have to say that at time engineering was five years. National merit scholarship was four years. I'm not quite sure how it happened, but somehow Cornell found a year and a half worth of financing. And so I explained to students this morning that be aware that you are valuable. Yeah, I didn't realize at the time I thought doing for me, but I didn't realize that I was doing for you as well. So that that's an understanding that has come to me later years that the student is the most valuable resource that we have here. So that got me to Cornell engineering was not a question. My had a high school guidance counselor, Mrs. stamps it and we discuss what I should be doing. But I took adaptive EPA amputated and adaptive know whatever the word is for what you could do. Well, I took those tests and I had two choices. I had engineering and I had order to get to the disaster happened. Phenols lawyer. Now, the reason for the lawyer was that I read every period mentioned books there ever was. And so I knew everything about very basic law and nothing probably about real law now. But anyway, I went to engineering.

Now, a high school was so small that our class size was typically small. Trigonometry, I was the class. The Mrs. Thompson who taught boasts, bath and other stuff, uh, gave me the book. It said the exam is on this date, be ready. So I did, I did all the exercises and all the books and I was ready. Now, unfortunately, I missed a question. Perfection is expected when I only got 98. Mrs. Thompson with battle for me because I explained to her that my answer was in fact the correct answer. Do you want to Albany and convince them that both answers are acceptable? Mla and I got my eye on it so that another influence was minutes times. But Mr. stamps, that was also on the damn damn committee because at the time that we're going to put flood control DAM north of Upton and wipe out the whole rest of the valley. So I got a good view of political activism because we didn't learn a whole lot of biology. What we're learning a lot about dam building and NAM defeated at that again was business stamps. That's how I got to Cornell.

I didn't have enough to buy food, so I had to work for a living. One of the worst shocks in my life was my first chemistry test. Yeah. Well, it was shocking was all of this to other students were saying it was it was rough. And I was you, I thought it was pretty easy. I failed. Not by much, I'm going to 59, but it was still failing. And then that caused me to reassess what I should be doing here. So I took a job at Willard Straight organize my schedule and gotten a lot better and that was the last one I failed as well. So we do learn our life lessons. I think that's enough for that question.

Yeah, I know that's a pretty thorough answer. You almost answered all the questions so that, you know, so at a, I'm a little bit afraid to ask this question, but I think one of the, one of the things we pride ourselves in as academics is the impact on people and especially on young students. Helping them find their way, understand your strengths. So can you talk a little bit? I mean, who were the role models at Cornell? Who are the people who had the biggest impact on you?

Well, I'll, I'll try on that. But it's not going to the answer. You want to hear it? Because basically, through our life, I was pretty much self-motivated, independent. So I remember laboratories where we had a team laboratory. I would write the report with the blanks where the numbers go. And we go in, we do the experiment, write down the numbers, do the calculation. And, you know, I live teams that very well. So, but I'm not sure that I got an inspiration from the distance because it was a team effort.

As far as professors, the one I remember most even now is not for what he taught, but for how you ask questions. And I remember the final exam question verbatim. Was, can a Cadillac push a Volkswagen bug across the road without the formula, basically parcel for the Cadillac to move the car out of its way? You know, that that's an engineering question but not phrased the way we would expect that to be. You don't expect What's the moment of inertia will not work, or what's the coefficient of friction that yeah, This one. Yeah, here's the problem. And yeah, so yeah, I think about that question and say, I could still solve that. But it was really frightening at the time because we hadn't thought about putting the pieces together.

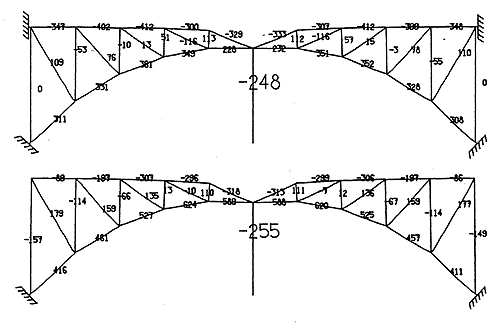

And the and then when they got into the industry, you know, what surprised me was how the simplest things were the most important. The two most informed formula, we're Mc over I and p over a. And if you use them, maybe with a coefficient or something. But you could do almost everything in designing a nuclear rocket with b over a and Mc over I. And so I learned that it's easier to take an exam if you understand the basic concepts and derive everything else. Damn time. Now so and a third skill I had was, I could remember lectures verbatim, just a couple notes in the margin, and then I could replay them. So I have to think that I'm not your normal student. I am who I am. Self-motivated. Hobo? Yes. Every milestone motivated. And I think I knew I had to be done and I went data and you did it. I didn't nearby beating a stick over me or whatever. And those are the best students, by the way, amylase, right?

So, so, so just moving forward because that I found as a, an academic who's advice, some really outstanding PhD students. The traits you describe are things I recognize many of these students. So you left Cornell, went to work for Westinghouse? Yes. I want it to do why I didn't declare engineering degree and my masters for engineering. So I want to do nuclear, but I also was interested in space. So a nuclear rocket, rocket was the Mars rock. And Mars mission. And we were going in 1980. Now, obviously that program didn't go very far. It's still floating in the wings somewhere, but I'm waiting from calleds a help us out here. But it has nap and yeah. So yeah, that was Westinghouse. I got there with my nuclear degree and they said, Well, we really got enough nuclear people how to bone, you can stress animals, mouses, and sign it. Yeah, That's why I learned PRA and MCI were born, So I I did quite a bit. But they have a graduate program. And my supervisor came to me and said, Can I put you in for the PhD program? And being young naive, I said sure. That, you know, not not treat recipients and deliver. The next fall, I was back to three courses for trimesters, trimesters per year, and a full-time job. And there's nothing like driving to Pittsburgh and even try to find a parking space. Yeah, that was a stressful part of it, was finding the parking space for the evening courses. But I got through it and came dissertation time. And I approached it in my usual creative or dumb, depending upon how do I look at it? I wrote up a detailed proposal, what I was going to do, eight pages. And they said, okay, that looks good. I went off at three months later I did it. I wrote all the software where all the graphics wrote all the dissertation, and Westinghouse printed it up for me and I walked in with eight volumes of PhD dissertations that I've done. Where do I get my degree?

Now, the loophole was you didn't have to do residents if you're working interrelated, how does nicely then suppose though that no longer there, it disappears several days after I left. And so you say I make, my advisor disappeared also, he went back to South America, although there was some turmoil at a time. So the just curious about how you fit it in. So did you go to school that my uncoded you? They ended the program. So I was able to do all my coursework. It was three courses per trimester, three premises a year. So it was 2007 courses. And yes, it was. And it was about three-quarters of our drive. But yeah, that's yeah, I don't understand suffering very well side I just suffered through and that's that's what I had to do. So that's what I did know.

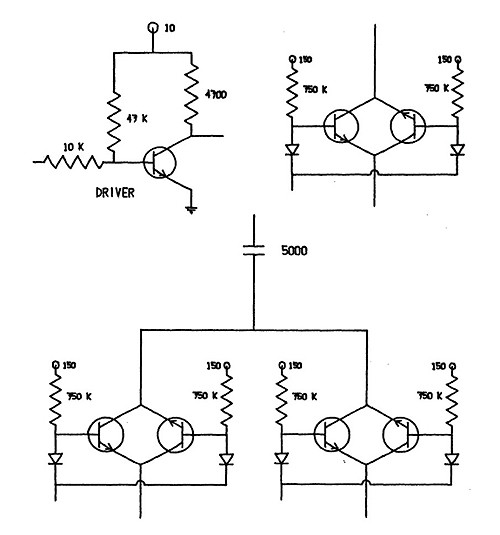

Awesome. So look, my understanding is that the, you know, the the the platform that be describing those answers, yes. Basically started out of that the later days of Westinghouse. Let me tell that story. Yeah, of course. That we had a problem with. Our design wasn't perfect. And we had an axis symmetric problem where something was cracking. And I hadn't no tools to work on this. I said, well, suppose I make a network of springs and see how the load flows and see if I can learn anything from that. Now our sponsors were Joint Atomic Energy Commission and nasa. And so I waited for review and they showed him laugh. And I don't try to learn anything from them. They said, Hey, that's what Ed Wilson is doing at the University of California, Berkeley. Why don't you go on top then? So I did, I went out, solved the problem, brought the two boxes of cards back with me and said, Okay, backtracking a moment.

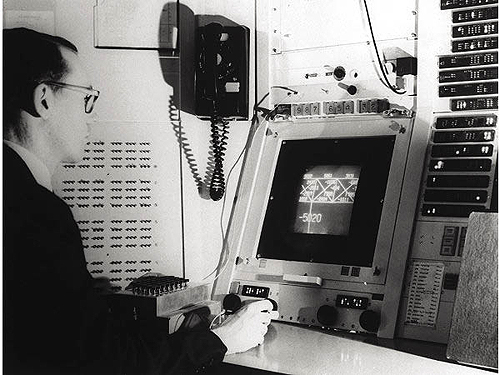

I never saw a computer at Cornell. Thank sense. So when I got to Westinghouse, they had a computer and they taught me a class in Fortran. And of course I loved it because you do it once the stays done. Yeah, I was banging out equations on a calculator, but I program them and I know that was it. I can take that half the day often or run 10 times as many analysis. I discovered computers. So then I got to software. I brought in a software for a couple of colleges, universities and government labs. And of course, be, who am I? We wrote them all and make them better or make it easier or whatever on or maybe just because I don't like to write it. But anyway. So anyway, I did a two-dimensional axis symmetric. I did two dimensional planar up programs for shells or programs for plates. I wrote programs for three-dimensional solids. And then I looked at it and I've done the same thing 56 times. Why don't I do it all at once? So I went to the west thing else research labs and said, I would like to develop software. And they said, we'd like you to run your stress group at time I was the manager of the stress groups. So I was discouraged. In fact, these literally said stop, keep on. She gets reflected in the morning and go back to managing stress group.

My philosophy on management was within baskets gets to I, somebody will tell me what what's important and I'll work on that. So yeah, I was I was not strictly management material, but I managed to fake it enough to do the job. But then you, then the, this software to do develop became successful as a product that Islam. And basically I half ago that I had, it was clear that the handwriting was on the wall. They saying it was clear that we were not going to Mars. And if we don't go to Mars, we don't need this thing we're working on. So something's gotta, gotta go and it's probably all the employees and all the software and everything. So I went out looking for a job there. And to do what I wanted to do, and I could get either one, but not both. So I started a company.

Now, people, okay, they say, Well, isn't that a risky thing to do? How could you do that? And I had job offers in my pocket and I had enough money to last a couple of months. And I could go out and do consulting at any number Westinghouse locations and others. So the risk was not that great and the rewards turned out to be quite, quite massive. So those were hard time developing software because you'll use punch cards, carry them into the computer. You would run the job, put the job into rotten, you wouldn't run it. It runs sometimes night, you go in the next morning, look at and find out why never went right. They find out, well, what went wrong and fix it, put it in again, and go off on your consulting job. Come back in the evening, you look at again, it's audio. So in that laborious manner, we actually developed some good software. But it's no, nothing strong or as much different news stories about spilling all your cards. So there's always a diagonal line from the top of the deck. Everybody puts a diagonal line. So when, when not enough, when you dump the cards, actually it's a card reader people that pick them up and they go and they give you back a pilot guard and say Sorry about that. So yes, the line on the top of the cards is in fact true. Also the Christmas wreath. And also true.

Well, good Sue though you so again, fast-forwarding 990 fork was the year yeah, I'll use old. You sold ANSYS and US did on the basically, the question is why always, and the why was it got too big? I like programming. So my philosophy was I'll manage on Monday and our program on Tuesday, Wednesday, Thursday, Friday. At some point, as you get to a certain size, that model doesn't work anymore. At that point. Now you've got conflict. I'm not good at conflict as Jeremy, I think. So. So at that point, I said somebody else can run this. I didn't solve a vessel that didn't exist. So I sold it to TA Associates. They took it over and put it allows the manager. But the second one they got really right. It has thrived dramatically since then.

So I'm going to ask you hard question, okay? Yeah. So sight of the the sort of technical accomplishment, what are you most proud of? Your time advances of time at Ansys. There were things I called I named power something. There was power graphics, there's power dynamics, wasn't thick, I'll put that there were those and those words, signs, we got order of magnitude improvement. In one shot. The graphics went from slow to flash. Also, I did a, a user interface which was long before Windows or anything else. In fact, IBM put it up for a national award for design. And it was a little slow until I got a little book that explain how to do graphics without doing multiplication and division on just the inner. And it sparkled. If it was just phenomenal, that things that were taking slow, we're instantaneously things with flashing and so on.

Another one that comes to mind is when somebody came to us and gave us a color graphics terminal. Now we've been using tectonics terminals that just draw lines on a green screen. Here's colors. So what's the obvious thing? What we'll call are the ones who did that, not colorblind. So as the story we did, I call it, people said that first. I forgot. I call it the polar and say, what do you think of this? They said, yeah, I said, well suppose we fill in the space. So instead of calling the line, we call it the areas magic. You know that everything now is done that way. But it was just the inside of invert the problem. Don't color the lines. Go to the spaces between the lines. Yes. So things like that. I remember well, there are times when I said, Hey, I read it and we celebrated and, and it turned out to be a dot. And then I had another one that we can make great strides here. And I programmed it all up and it had a fatal flaw. Yes, I don't remember those other than there was a problem, but I don't think about them a lot. And that's good.

That's really good. So again, I'm going to career jumps. So this next question, John could spend two hours because I just isn't an hour long talk, so just bear with him here. Alright. So you know, then you left ANSYS permanently? Yes. And, you know, I I'm just listening to you and imagine that We're still full of energy, full of creativity. How did you decide we didn't, this wasn't a minute and just kept the peace because I spent ten years as a consultant for it. Yes. Yes. Okay. So eventually, that was not too long ago. I found I was paying more for the lawyer bills and I was getting from that answers all. At that point, economics says, it's probably not worth doing this. And, you know, my, my consulting job and answers is interesting because I could do the projects and nobody else wanted to do the ones that had no glory attached. Ansys would stress test the software, trying to solve bigger and bigger problems to stay ahead of the market. And if they find some limitation, they call me up, say, Hey, yeah, make this bigger, like 1000 times bigger. All right. Now so often it was something I said, well, we'll never have more than something. And so that limit was built in. And sure enough, a few years later, we had, you know, we thought we'd have a customer who had more. So our objective was to just get there before the customer doesn't fix it. So the customer never say that that was quite successful. Now, what was your question? Not somebody I wanted to get you'd be unanswered. I'll beyond that. Yeah.

So I wanted to get you to the energy and the answer. We get there. My oldest son got solar panels in California where different market interesting. And I said, Well, if I can get solar panel, I should have solar panels. So I got solar panels and I say, well, this is a good thing actually that I can get cheap energy and it's green, but it doesn't have to be, you know, I could sell it on the economics. Yeah. You can't afford not to do this as opposed to, oh, it's green. You gotta do this. You can't sell. Mean that you, I'll do this by each cell. You can save a lot of money doing this. And it's green. Yeah, that sounds pretty well. Dogma. And that now I'm doing the same thing with electric vehicle. I'm having more trouble because it's green, but I'm not sure the economics are there. Yeah, so I'm, I'm having to learn a different strategy which I haven't figured out what it is. It's got muddy. Yeah, it was just, these are interesting technical problems. Notice I didn't do windmills. Now, no idea. I can't put windows on my on my roof or on my property. So I've got no interested windmills because the zoning does the lock so that I can to electric vehicles, I get a solar panels. So those are the ones I chose.

And so talk to me, you know, So tell me a little bit about, um, I mean, this is great, but tell me a little bit about what drove you to found green key village. And he was actually the contractor who had done my solar, came to me and said, Hey, I'd like to do more of this as a piece of properties become available. It'll hold a 100 houses. And why don't we create a Green Village? And so can you tell the audience what green key villages I'm going to evaluate? Is it all? And all green community. All the energy is developed through solar panels. Every house as solar panels. Every house is also designed to be as energy efficient as possible, is gone blown and installations. It's got high resistance windows. Everything is designed for energy efficiency. And we basically warranty of them to be net 0 energy. We don't say net 0 price because electric company keeps adding monthly fees. We're not covering for that, we're just covering for the the energy. And it's been relatively successful. We're about 50 houses in 2019, 20 that are available.

There is a story behind the land acquisition. It was about a 100 acres and there was a builder who had put in roads and some sewer lines and so on. Unfortunately, there's a downturn in the economy and he suffered. So the bank got the property. Well, not the end of the story. The bank with under and another bank got the proper. So it was on the market for around about $990 thousand. But he said to me, I think we can get it for half that. We bid a 0.5 million for it and got it for 650. Yeah, so that was sort of the impetus. We've got this piece of property as partially developed. We can do this. And it started slow. But now, well, the supply chain problem is labor problems had us because we got it house sold, but not close because electric meters not in, yeah, in the lecture bidders with delayed three weeks because for some reason micro meters or don't wait three weeks. Yeah. Yeah. So there are real life issues that focus around me are nothing to do with renewable energy. But we've prevailed. We are, We're still solvent and building houses. There are about four or five other infrastructure.

So one of the things that when I read about this project, I think of the fact that Cornell ones to be carbon neutral by 2030 and see and use someone who's actually had this sort of underground experience or not. But, you know, that, that was the purpose of it for me, It's a laboratory and a demonstration. This is what the world looked like in residential. And I've had a goodly number engineering Deans. You're invited out to look at it. And I've had it brings peace and yaw. The environmental groups take tourists and so on. So it's a debit for me, it's a demonstration. And so, and so big lessons because we have the same principle as well, we would like to use successes on campus to teach the world, to do certain things, sort of living laboratory concept. I wonder if you have any advice for us.

I've got another story. You'll see. I think you have to suffer through this that the Chancellor at Pitt came out of Washington DC where he ran the bureau standard laboratory. Him, if he Seidel up to me one time at a board meeting. He said, China, we've got a net-zero house. You really ought to see it. I said, Oh, is it lived in. He said No, but got an instrumented. I so I've got 25. They're all if you come to Florida and I'll show you that it's not in anyway, ask your other questions and then we'll actually but you answered your own question. So my y I have allowed my question was lessons for us, lessons for you, lessons we'll Cornell. So we're thinking, now this is not a few houses, this is a community of 30 goes, as you heard me say my lecture this afternoon. I think Cornell is an interesting case, because Cornell's energy need is not electricity so much as heat. And heat is a my opinion, understudied phenomenon. Yeah, nobody has focused recently on what is the problem with a time delay? Heat is hot in the summer called the winter. What can we do with that? You know, the answer to that. There's gotta be take the heat from the sovereign put in the winter, he took a course from the lake. Now that didn't work. So you need a hotlink. Now you're looking for it and geothermal. You're looking for hot lake? Yeah. I'm not told that you're going to find it. So I gotta look at Plan B and C. But plan B is basically find a way of storing large quantities of energy. And if you phrase it that way, The way to do that as phase change. And I tell the whites pond story briefly, whites pond prose. Every winter we chopped up the ice, we put it in the icehouse, buried and sawdust and use it all summer. Yeah. So what's the inverse of whites pond? How do you chop up the co the the heat of the summer, store it in whatever you're storing in the face. During the winter. Ice is a phase change material as paraffin as it turns out, better ones, Yeah, yeah.

So we are going to veer off rates. So one of the things that you've done sentences, you've become an incredible, you and Jeannette will become incredible philanthropist giving education initiatives, not just here at Cornell, Pittsburgh, and many other places. I wonder if you can tell us a little bit about some initiatives that you've supported with your proudest. Okay. Well, let let me ask the question. Didn't ask that was why are you doing this? Well, you can answer the Atlantic. The why you're doing this. As I said, engineering was good to me and it's given to me. When I gave to me, American bank note company gave to me. A lot of people gave to me. And I'm certainly not taking it with me. So I've gotta figure out what's the most creative ways of giving it back. And I think we've been quite successful at that. It's not all gone. We've discovered a charitable gift annuities with Schar for a poor boy was scared to death and being poor. Charitable gift annuity is a guarantee contract. Money forever or until we bought by whichever comes from. So we do that. Well, people have also asked me, how do you our UCL successful as philanthropy? How do you choose such interesting and beneficial project? And I say, I don't, I go to the university and say, what do you need? Yeah, or they come to me and say, Hey, we want to study teaching methodology. This is what's most important to us. I just talk to Helen. She asked me with latest gift, how do you want to fine tune it and it's not I don't know. I don't yeah. You will know better what what you need at that time that I could ever know. So, so basically it's a matter of listen to what you want. Maybe helping us think through, but not necessarily saying that's the only answer you may want to go some other way. And I'm not going to forget that.

Yeah, that's great. So, um, so look in the interest of time, I'm going to ask you just one more question. Okay. That's that's the sort of question that Dean has this grade. So during the course of the day today, you interact with adults or I had a great time that you had a great time. I can tell from the talk at lunch. But I guess the question is, what gives you hope? But I mean, based on these interactions, are there gaps, are there things we should be thinking about? Does the college in terms of how we educate?

Well, thanks for your basic rules and I'm emphasizes both courses. One basic rule is follow the money. Yeah, it's all economics. Now, if you can't do the economics, nothing else follows. So now, who benefits? I've struggled with Professor Gao and he's talking about health. And I said, Okay, who benefits from a healthier population? Who is going to be behind us? Who's going to make a lot of money if we have a healthier population. And in my, you know, my first thought was insurance companies. Yeah, there's nothing better for an insurance company than a healthy person if they're insuring their health. Say, you gotta find out, yeah, you can't just say, let's make the world healthier. You're going to find out who has the money and the desire to benefit for being healthy. So yeah, that's a core lesson, but I don't think you've ever hear that taught. So systems and yeah, I was accused the system psyche. And I'm complimented by that because I think that's probably a good thing. And probably something that Cornell as a leader.

And so if I can paraphrase, so what you're saying is that we need to basically allows students almost as a knee-jerk to marry the engineering systems and economics is that there's another way to consider that those are the driving force. No matter how theoretically you are or how intelligent you are if you can't get the money behind it or convince somebody that this is the future. It's going to stay at the university. Hi on the shelves. If you can get somebody excited about it. Who's got money? You know, that? Yeah, I was almost convinced we're going to get fissured energy, fusion energy. Just because the professor says, Yeah, we're going to do this. There's going to be breakthrough as here's one already. It's not 30 years off, it's only 20 years off. He and I are going to talks or because we don't necessarily agree on the timescale, though there's some there's some really interesting things there, but I'm going to stop because John and I can go on. I mean, we have a lot of similar interests. So what I would like to do those open things up for members of the audience, including by the way, persons on Zoom have any questions? We have some runners in the audience and I think you can probably just saw, unlike with permission of the controllers, to ask you a question from from zone. So any questions from the audience for John?

So it's hard to get first app, we got one good or free.

Hi John. Hi, my name's Sam. I'm a student here. And I guess one of my big questions is, how do you go from a technical degree and a lot of technical experience out of college and starting your own company and learning all the skills that are required to manage and start a business like that.

Well, let me be clear that I didn't know where I was going when I started. And I said explaining to students via lunch, that's life. Yeah. Yeah. Just just go somewhere and, you know, the passable but you have no idea where it's going to be. Yeah. So when I started as a software company, I expected to get maybe five employees and writing software. And just because we like to write software, I had a I think it's the tenth anniversary ceremony was 200 employees. And I told that particular story and ask the obvious question, what are you all doing here? Yeah, but yeah, but we also had a philosophy. We don't hire anybody, we can't pay, you know? So they were a side effect of the fact we were quite a cash cow. And it's much bigger cash cow now than it was then. But to have predicted when I first started where it was going to end up. Don't even bother wasting the time. Go somewhere this interesting. Go somewhere that you can at least pay for your food and then push it beyond that. And if it doesn't work, find somewhere else, this don't try to predict life. It's, it's just, I think anybody here can probably test. Yet. You could never have predicted where you ended up with. Whereas don't stress offering 55 to find a good job, do something interesting and the pieces will fall within a similar with education, I say to people, go to the master's level, but don't go beyond that until you go out and see what the real world is like and what's really needed. And that if you're really lucky or even if you're pretty good, yeah. The company will pay for whatever else they need from you because you are valuable. I keep emphasizing that. I don't think at the age we start out, we realize what a valuable resource we are. But the people who were working for, I hope, do.

Great. So couple other questions.

Hi, I'm David Erickson, director of Mechanical and Aerospace Engineering. We've met before. I dive in. Let me, at Cornell now we have a lot of students that go on and did this same kind of do the same kind of thing is you got work a little bit, start a company and many of them do all kinds of great things on the way. Making lots of successes, maybe not as big as you, but, but in many cases. And I'm wondering, I assume and all the success you, how you must have at some point made some mistakes early on in the day's events as well. I don't want no, no, No one. Okay. Well, then I'd have to ask question. Yeah. Yeah. Sorry. Carry out. I've got curious looking back, you know, all the things that went right. What are the things that we couldn't take away?

Well, let me be clear. There have been a lot more failures than successes. One success wipes out a whole lot of failures. That's right, yeah, for example, I invested heavily in photovoltaics. I had a company and we had a goal up a dollar a watt. And that was an ambitious goal, is now 35, 40 cents a lot and the company doesn't exist. Yeah. So yeah, some things are within your control, some things are not. Now, I personally say we got to a dollar Watt were successful what B, and move on. So what, what's, what's the big learning then per? Well, that's a big learning is also a good money after bad. Good. Let it pull the plug at an appropriate time. Don't don't try to ride it all the way down. Like your memory. It'll give us another field isn't somebody who's very busy?

A Zoom question? Yes, we do have a Zoom question. They want to know what kinds of problems would inspire high-schooler to choose civil, mechanical, bioengineering today in all areas of engineering. But I think, in my opinion, is engineering as the world's greatest career. And it's also one of the most respected. Now, let's please keep it that way. Yeah, don't, don't screw it up. Because engineers are what make the world work. I think the answer to that is yes, show people what engineering is. Show people what engineers do, show how exciting it is. Show him how much influence they have on the future and show him all that and they're not interested in it. He would probably it's probably a lost cause and move on to the next person.

Hello. My name is AACU being moody. I'm a senior ECE. So I was wondering. So in terms of knowledge, the relation between knowledge and engineering, when you go to solve a problem, how do you get all the background information you need? Say to solve a problem or what are the key points that you target?

Let me go slightly sideways on that. When I first started teaching ANSYS, I said always start small. If you're going to go and auto crash analysis, you have one mass rep a car and one spring. Understand that? Then you can start modifying. You can put the mass on wheels and allow it to rotate a little bit when it hits a wall, and so on. So each, each new simulation should be a endorsement of what's happened before. Not a surprise. Yeah, if you get a surprise and simulation, you didn't understand the problem. Now, I'm not quite I think that relates to what your question was. And that is basically start at the start small and work your way up. Don't try to solve the big problem without understanding all the pieces to it. I got you.

Thank you. And was there a Zoom question?

Okay. So looks so i so I'm going to wrap things up, John, to say train first, first. Thank you. And a manager, you're an incredible person to interview because interviewer doesn't have to ask the questions. The questions I had for the question gets answered.

But but look, so I want to just say on behalf of the college, we've had this tremendous run a 150 years as a college graduating leaders who by virtue of their research, their entrepreneurship, and just they're just Ackerman. Build technologies, build companies may change that impacts the world. And in my first year as dean, one of the things I've enjoyed the most was getting to meet leaders like you, who in many ways don't just exemplify, I think what is good about our college and good about our society in the ways that they usually think about, but who are actually values-driven people, people who consistently demonstrated commitment to some sort of higher purpose that ultimately has the impact on humanity.

This is the sort of character or characteristic, I would argue that brought me here to Cornell 21 years ago. This idea that you have this Ivy League institution that embraces the best of the IV and the broad education that Ivy League schools provide. But sort imbues it the technical rigor, right? So you can create the John Swanson who goes out there and does something no one else has ever done. But then at the end of that career turns around and says Mike, you Just out that I'm just going to give it all away. I'm just going to support initiatives and having higher Taiwan thing. Years ago we set up trust for his three boys. So they've got there. Yeah. I don't have to fear from them because I could live forever and they're set anyway. And if I go, they don't get it. Well, so that's the mess. That's nice security. Now the other hand, charitable gift annuities would make me very vulnerable to colleges and so on. If they say, Oh, get rid of him, we get a big a, big a Daubert been done. So if something happens to be, I I've pointed people to the various places to go. Look.

I'm sorry, I interrupted you. I I I should have started by saying the question and answer phase is open. So this is where I get the Buddha speaking to see you.

Hey, John. Congratulations. I mean you are you an example for all of us? And it gives me tremendous pleasure on behalf of my colleagues in the college to present you with our distinguished alumnus award. I think as you know, this award is relatively new in the college's history. And I'm glad to be the dean presenting this award to you. And I have Asiana, I think a view, Q&A. I think a view. I think of you as the engineers engineer on someone I admire a whole lot. So congratulations Jenn. This this is where we get to it.

I'll take it now, but can you tell me? Yeah. Yes. You should just leave it then. Never mind we're driving application or if they put into mine and I get to shake your head. Yes, I'd be fun to get grants and shot. Thank you. Thank you.

n5321 | 2025年6月8日 17:20